About

Home » Engineering & Built Environment » Departments » Department of Mining Engineering and Mine Surveying »What can new students expect from our programmes?

The Department offers qualifications for Mining Engineers and Mine Surveyors up to a Doctorate degree level. Both qualifications are accredited internationally. The Mining Engineering qualification is accredited by the Engineering Council of South Africa (ECSA) and the Mine Surveying Qualification is accredited by the South African Geomatics Council (SAGC). Both qualifications are supported by the mining industry through the Mines Qualification Authority (MQA) and the Minerals Education Trust Fund (METF) who advises the department regarding curriculum development and student placement. The Department co-operates closely with the other three mining universities, the University of Pretoria (UP), The university of the Witwatersrand (WITS) and the University of South Africa (UNISA) education and research matters.

Mining activities includes surface mining, mining equipment, minerals processing and environmental aspects. Our graduates are prepared to deal with all of these aspects and develop their own businesses out of any opportunities they identify. We are investigating space mining and deep sea mining for future mining operations.

Both the degrees will prepare graduates for the extremely difficult and alien environment of mining. Our graduates are expected to think clearly and make important life-or-death decisions in a dark, hot and humid environment and act correctly every time. As such, the courses are designed to develop their confidence and knowledge in every aspect of the value chain. New students can expect to be introduced to a whole new environment and an entirely new culture. Every person completing a qualification here knows that they are “miners” first and then only do they specialize in their specific area of expertise. In the beginning everything, including the language and terminology is completely new.

We recommend industry exposure, preferably before starting your studies but we understand that that is not always possible. Students must be mentally and physically healthy and will have to undergo a medical clearance before starting work on a mine. The work requires you to be physically fit and able to tolerate heat and confined spaces. Upon graduation you will work towards a Government Certificate of Competency which is a legal appointment into a position which carries great responsibility and daily challenges

Why should students come study Mining Engineering or Mine Surveying at Department of Mining Engineering and Mine Surveying of the University of Johannesburg?

Our department has a rich history and our graduates have a proven track record in industry. If you start work at a mine, the chances are good that your supervisors will be alumni from UJ. UJ has a hard-earned reputation for developing practical “hands-on” production driven mining engineers and Mine Surveyors that are immediately productive after graduation. Both qualifications will enable graduates to be employed in the production sections of a mine and carry a legal appointment through the Mine Health and Safety Act. This position carries great responsibility and daily challenges. The work is mentally and physically challenging, it requires a lot of perseverance and dedication, but the rewards are great for those who persevere. Interested persons needs to have an inquisitive nature whom enjoys solving poorly defined problems. The two degrees prepare graduates for the extremely difficult and alien environment of mining. New students can expect to be introduced to a whole new environment and an entirely new culture. Our graduates are expected to think clearly and make important life-or-death decisions in a dark, hot and humid environment and act correctly every time. The courses are designed to develop their confidence and knowledge in every aspect of the mine value chain. Every person completing a qualification here knows that they are “miners” first before they specialize in their specific area of expertise. In the beginning everything, including the language and terminology is completely new.

Industry Partners

Mining Engineering Education South Africa (MEESA)

Draft press release on MEESA, facilitated by Wits School of Mining Engineering

SA’s mining school heads form collaborative body

“To allow more cooperation and information-sharing, the heads of South Africa’s four university mining schools have launched Mining Engineering Education South Africa (MEESA).

Established last year as the Mining Heads of School Forum and recently re-branded, MEESA is currently chaired by Professor Ronny Webber-Youngman of Pretoria University’s Department of Mining Engineering and includes his counterparts Professor Cuthbert Musingwini of Wits University, Prof. Hennie Grobler of the University of Johannesburg, and Mr Israel Dikgwatlhe of the University of South Africa.

Emphasising the need for closer collaboration between mining schools, Professor Webber-Youngman highlighted research, funding and work experience as key issues for MEESA.

“Since mining research capacity has decreased over the last few years, research collaboration is imperative in addressing the challenges the South African mining industry is currently facing,” he said. “The country just does not have enough researchers to be competitive in this regard. Our four schools look forward to collaborating more meaningfully in the near future in our research activities.” Since its inception, MEESA has already been able to interact more effectively with the Mining Qualifications Authority to collectively resolve challenges encountered by each of the schools. “I believe that a co-ordinated approach in dealing with challenges is one of the major benefits we all derive from this association,” he said. MEESA has also been able to collectively secure a number of vacation-work placements for their undergraduate students.

“Key to this collaboration is that there is more information-sharing across all four schools,” said Professor Webber-Youngman. “Unlike in the past – when each school had relationships with other mining schools internationally – we will now be able to strengthen local collaboration and leverage this to ensure more sustainable collaborations globally.”

Sibanye Stillwater Simulacrum (Digital mine simulation)

The Simulacrum development in the basement of the QK building on the Doornfontein campus connects an existing 100m tunnel linking a pump chamber used for the treatment of groundwater from the fountains situated in the basement of the building, with an existing cargo elevator shaft. The connection takes the form of a shaft station and cross-cut layout with access to a board-and-pillar coal mine layout and a virtual reality centre. Access to the experience is through a lamp room and crush arrangement where students are outfitted and equipped with the correct PPE and lamps. Upon entering the students descend one flight of stairs into a “sub-bank” and enter a men-and material conveyance “cage” which simulates vertical movement. The student exits the shaft through a door on the opposite wall of the shaft and enter a deep-level mine shaft station. From this point the student have access to a waiting place, refuge bay a shaft crosscut and the board-and-pillar layout. The simulation incorporates a shaft tipping area with screening, a simulated raise and winze intersection complete with scraper arrangement and ventilation doors. It is hoped that explosives handling and charging up techniques can be refined in one of the simulated cross-cut ends. Within this simulation various experiences including other mining layouts and scenarios will be accessed through QR codes placed at points of interest as well as the VR centre that will be to the side of the shaft crosscut. Exposures of geological features are available for mapping and teaching purposes in the main haulage towards the pump chamber. In the simulation, real water sumps, pumping arrangements and ventilation reticulation are being developed. The current water pumping arrangement will be monitored, and the information is planned to be relayed to a control room.

Mining blast simulation (Blast Wall)

The first of these blast walls was introduced to the Glencore Mopani copper mine in Zambia (Colquhon & Bouwer, 2018), the second was installed at the Murray and Roberts training centre in Carletonville (Cornish, 2017). The simulation is in the form of a projected full-scale mine tunnel excavation. This system appears to be a derivative of the CAVE system where a “low-immersion” experience is created using a hard drive and a “geo-wall” (Bowman & McMahan, 2010).

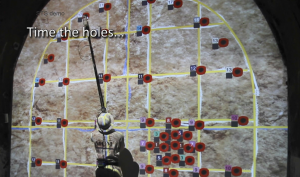

Students are taken through a sequence of identifying geological hazards, marking-up of the direction- and gradient lines on a smart-screen. Once the control lines have been marked-up, the student can mark in the blast pattern according to a survey design layout of an excavation 3.0m wide and 2.0m high as well as a stope excavation 3.0m wide and 1.2m high. Upon completion of the correct marking-up of the design, the student can sequence the blast with the correct blasting pattern and detonator delay. The blast is then simulated. Students can be evaluated on the accuracy of the marking-off procedure and blast pattern timing. An additional feature to this particular blast wall is that the student has the option of marking-up a stope blast pattern at a working height of 1metres. This requires the student to work safely in a crouched position without being exposed to an actual restricted environment. It is recognized that the VR will not replace the blasting ticket requirements but will provide safe and controlled exposure to the actual process before being exposed to real blasting conditions.

Virtual Reality (VR) Headset experience

This augmented environment enriches a physical environment with augmented displays that is superimposed on the participants vision providing additional information and data streams visible to the user (Khimeche & Wolf ). The infrastructure available in the mining laboratory was successfully demonstrated to other faculties at a Scholarship of Teaching and Learning Seminar in May 2019. It is hoped that the demonstrations will lead to cross-disciplinary research in the various aspects of VR in the development of curriculum and the impact thereof on existing pedagogy and didactics. The experiences are limited to

- An underground platinum mine where students can be taken through the surface entrance to a vertical shaft conveyance, travelling to an underground level and walking to a waiting place where the student can complete a pre-entry examination including temperature and gas readings, barring and watering down of excavations. The student can then proceed into a travelling way, up a raise into a stope. The experience requires the participant to perform tasks and checklist as well as confining the experience to the actual height dimensions of the actual mine. This requires the participant to move on hands and knees through the excavation with a height of only 1.0m. the experience is completely safe although the level of immersion can lead to discomfort in some users. As the experience is constrained in the VR world. The participant can simply “opt-out” of the experience simply by removing the headset. In most cases the instructor can through touching the participant’s arm or shoulder re-assure any distressed user.

- An underground diamond mine where students can be taken through the surface entrance through an inclined shaft walking into the mine. The rest of the experience is site specific but similar to the experience described above.

A small experience with “working at heights” where the participant enters an elevator that takes the participant to the roof of a building. the participant is then encouraged to walk on a 250mm wide plank over a city scape that is approximately 60 storeys below the participant. Participants can be acclimatized to exposure to heights and evaluated based on their perceived fear of heights