Research

Home » Engineering & Built Environment » Departments » Department of Metallurgy »

RESEARCH FOCUS

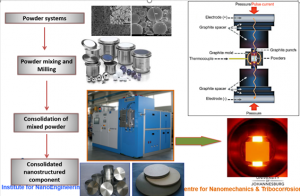

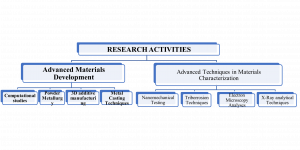

Powder-based techniques for processing and advanced techniques for performance assessments of sub-micron & nanostructured metallic alloys and MMCs with light-weight, high-strength, high temperature, as well as wear-corrosion resistant and biocompatibility properties for;

- Automotive and aerospace application

- Mining, chemical, marine & allied applications

- Biomedical implants

- Microelectronics

- Energy storage

RANGE OF RESEARCH FOCUS

Materials Systems

- Nanoengineered lightweight materials, High entropy alloy systems, Superalloy systems,Smart materials systems

Fabrication/manufacturing techniques

- Spark Plasma Sintering (SPS) technology ,3D additive manufacturing and Metal casting

Materials Testing and Characterization

- Microstructural (image) analyses, Functional properties, Mechanical and nanomechanical testings

Ore recovery processes

- Applied mineralogical studies ,Electrochemical analysis and predictions and Reduction studies

Characterization FACILITIES

- Suites of sample preparation facilities , High-performance optical microscopes, Tungsten Filament SEM, High-Resolution FE-SEM, Empyrean X-ray Diffractometer, Rikagu X-ray Diffractometer, X-Ray fluorescence, Atomic Absorption Spectroscope, Inductively coupled Plasma Spectroscope, High Temp thermal conductivity analyzer (2,800 °C)

Materials testing FACILITIES

- Micro and macro hardness testing facilities

- Universal tensile testing system

- High temperature nanoindentation system (800 oC)

- Hardness properties

- Fracture toughness

- Tensile properties

- Creep properties

- Fatigues properties

- Corrosion and electrochemical measurement facilities

- Erosion-corrosion and tribocorrosion measurement facilities

- Room and high temperature tribometers (1000 oC)

- Friction co-efficient

- Wear phenomena

OUR PROJECTIONS

Vision :

- From powder to advanced materials

- From lab scale to industrialization

Our plan is to upscale from lab research to product development, and start an SMME

Knowledge Know-How:

- Powder processing

- Consolidation technologies

- Integrity Performance assessment

Examples of development:

Lightweight metals

Smart materials

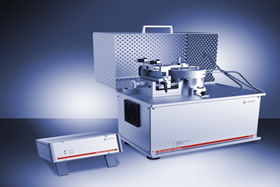

UNIQUE MATERIALS TESTING SYSTEMS

High Temperature

Nanoindentation System (800 oC)

High Temperature Tribometer (1000 oC)

UNIQUE MATERIALS CHARACTERIZATION SYSTEMS

FEG-SEM with EBSD and Tensile Testing up to 10kN

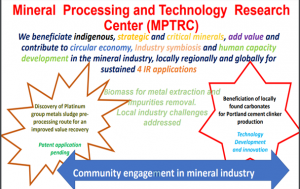

Research Centres

The Centre for Nanomechanics and Tribocorrosion (CNT) at UJ is an International Research Centre for knowledge and skill interchange in the field of Nano engineered and advanced materials research. The Centre focuses on skill training, capacity building and research opportunities for postgraduate students, scientists and engineers, in the emerging areas of Nano engineered and advanced materials with more emphasis on advanced alloys and metal matrix composites, Nano mechanics and tribocorrosion techniques. The Centre facilitates knowledge transfer between academia and industry/business through dissemination, promotion and commercialisation of innovations and inventions as well as offering consultancy services and advice in technology development and solving complex industrial problems.

The Centre has well-resourced laboratories that are fully equipped with state-of-the-art research facilities including Nanoindentation system, High-Resolution Scanning Electron Microscope with EDS/EBSD and multistage materials testing systems, tribological and tribocorrosion testing systems, electrochemical corrosion measurement systems, micro and macro hardness testers, micro-tensile testing systems and computational materials modelling workstations. The Centre has a shared-facilities partnership with the Institute for Nanoengineering research at TUT where the innovative Hybrid Spark Plasma Sintering system and other powder metallurgy facilities are housed